TESTLAB

Our test laboratory provides environmental testing for all industries. Testlab at a glance →

CONTACT DETAILS

Christian Kretschmer

T. +49 30 42188-438

You are here: Home » Accredited Test Laboratory » IP protection class testing

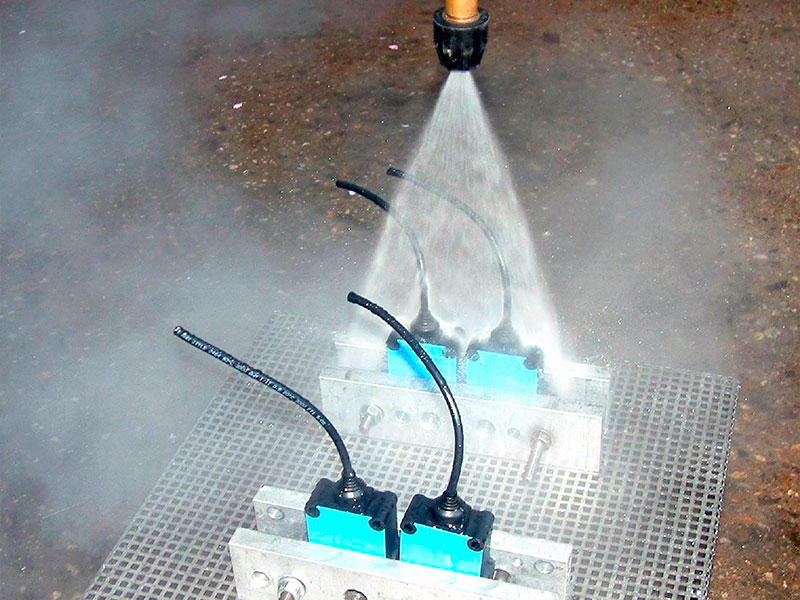

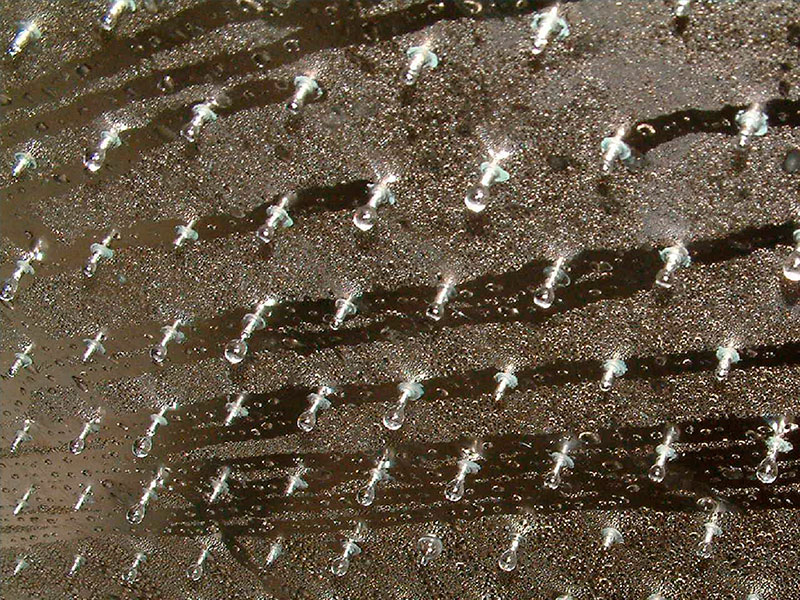

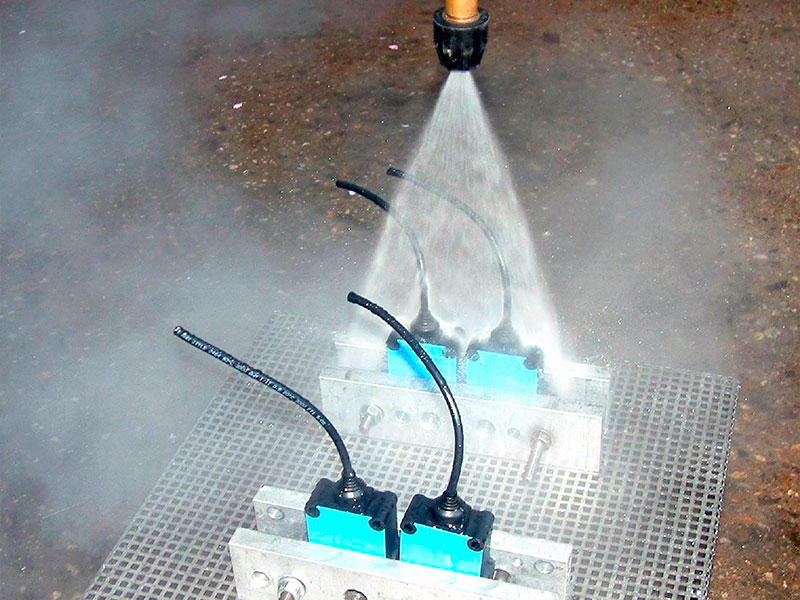

The AUCOTEAM test laboratory conducts protection class testing for numerous industries and application cases. In our accredited test laboratory we test dust protection, contact protection, foreign body protection and water protection, and also conduct sealing integrity tests.

Our test laboratory provides environmental testing for all industries. Testlab at a glance →

Christian Kretschmer

T. +49 30 42188-438