Mining Operators

Mining Operators

You are here: Home » Mining Operators

Customer-specific solutions for mining operators

Our tailored operational management and scheduling systems for mining and power station operators offer support when making decisions regarding the flexibility, efficiency and cost optimisation of production operations. We access the most diverse information sources for development – from current and historical process values, tabular specifications, database information, through to the satellite-guided recording of position data for large-scale equipment.

Contact our team

Our competencies within mining

- Tailored engineering services

- Consultation and training

- Flexible solution competencies

- Online geometry processing and visualisation

- Process data recording concerning the PGIM components of the 800xA-ABB control system as well as the Siemens WinCC interface (via OPC as required) and OSIsoft-PI

- Desktop-and web-based applications (2D / 3D)

- SingleSignOn for web applications

- Web-based users and user rights management with link to the Active Directory

- Diagnostic systems

AUCOTEAM work areas for mining operators

Range of services at a glance

We are actively involved with many industries that operate within the mining and power station sectors, and we make it our mission to integrate the hugely diverse interests of our customers into one effective overarching concept.

Description of work areas

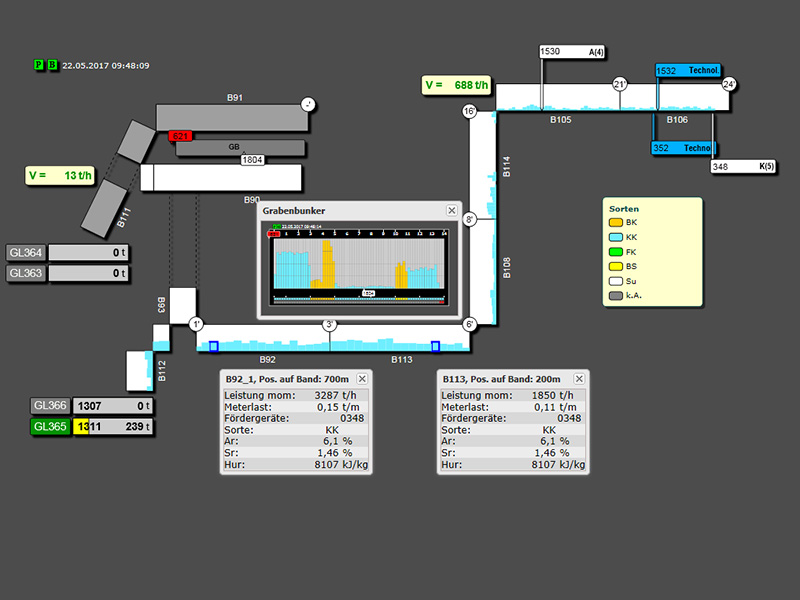

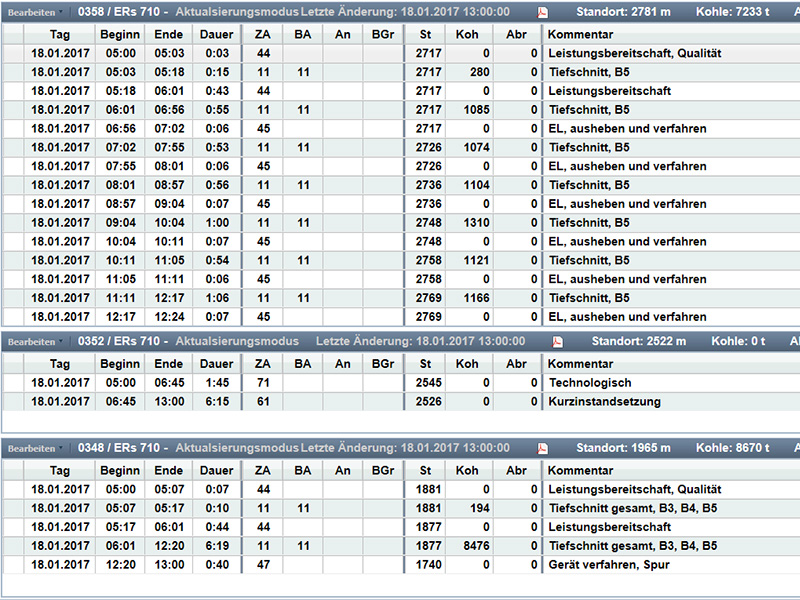

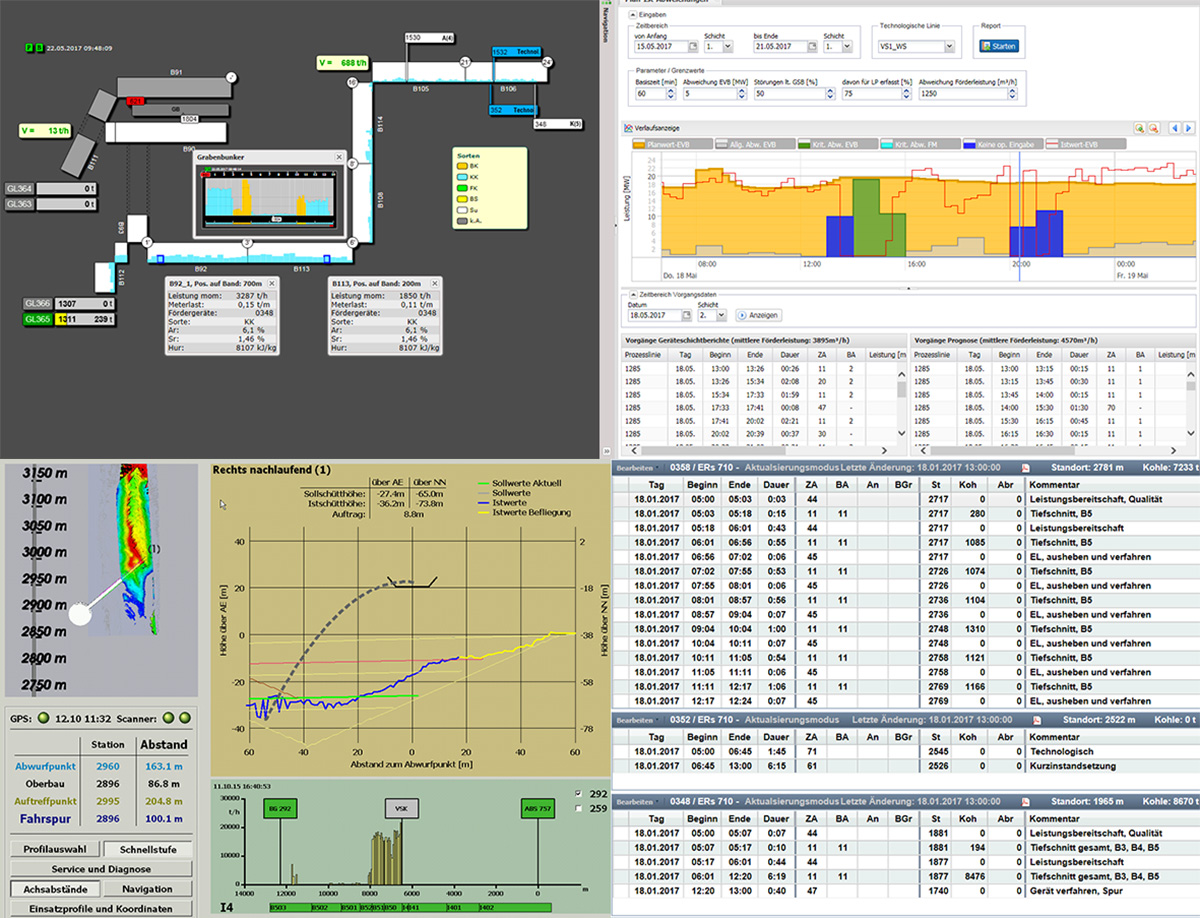

Operations monitoring

Automatic and interactive components for the recording, modification, assessment and visualisation of relevant operating and disruption and/or downtime events, as well as performance and consumption data

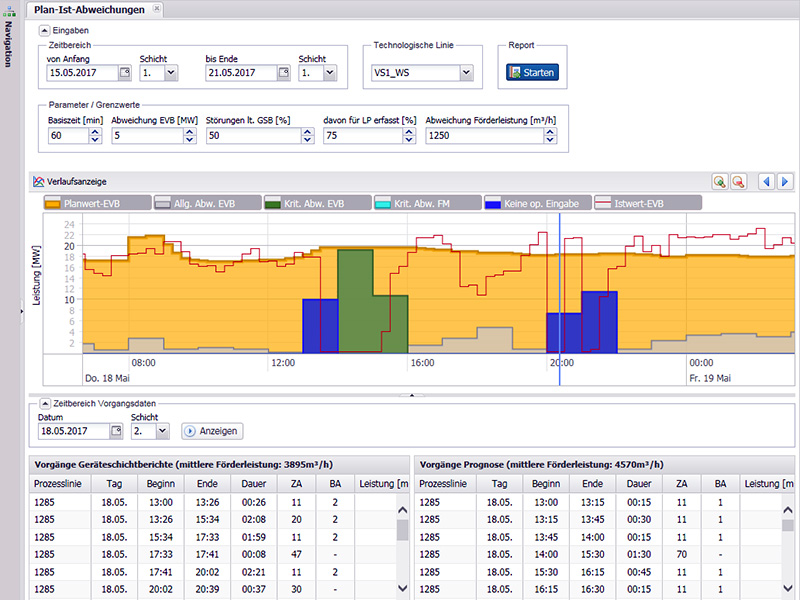

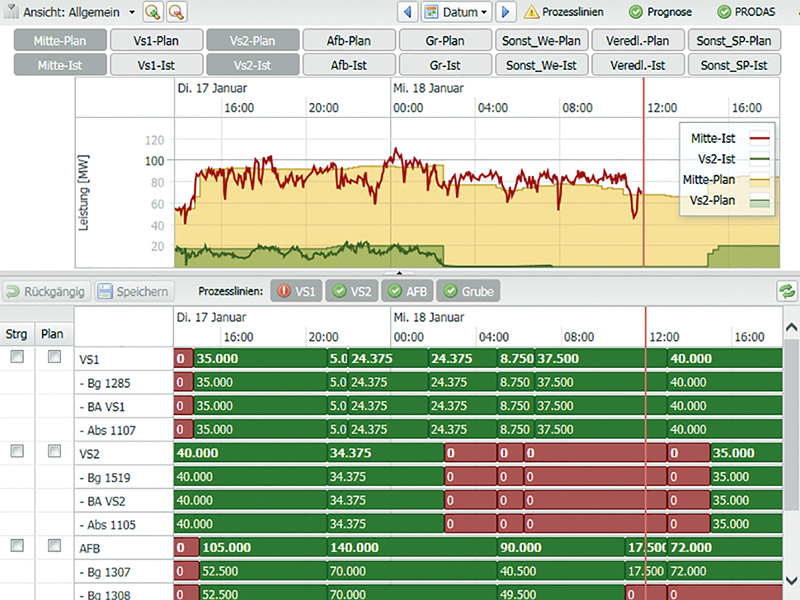

Load forecast

Forecasting of own energy consumption at the individual production sites, starting with the planning of excavation quantities and operational setups

- Continuous utilisation of results as part of requirement planning for power stations

- Collection and energy-centric assessment of production disruption events and unscheduled changes to plan, which lead to differences vis-a-vis the original requirements planning

Process data interface

- Access to different control systems / basic information systems

- Integration of virtual signals and forms / calculations

- Standardised application interface independent of the basic system

- Lack of physical / network-technical client proximity possible

- Live data / historical data

- Basis for diagnostic system

Quality Assurance System (QAS)

- Modular structure

- High degree of flexibility regarding the information to be disclosed

- Form of visualisation independent of modelling

- Web-based visualisation

- Flexible tools used to visualise production work

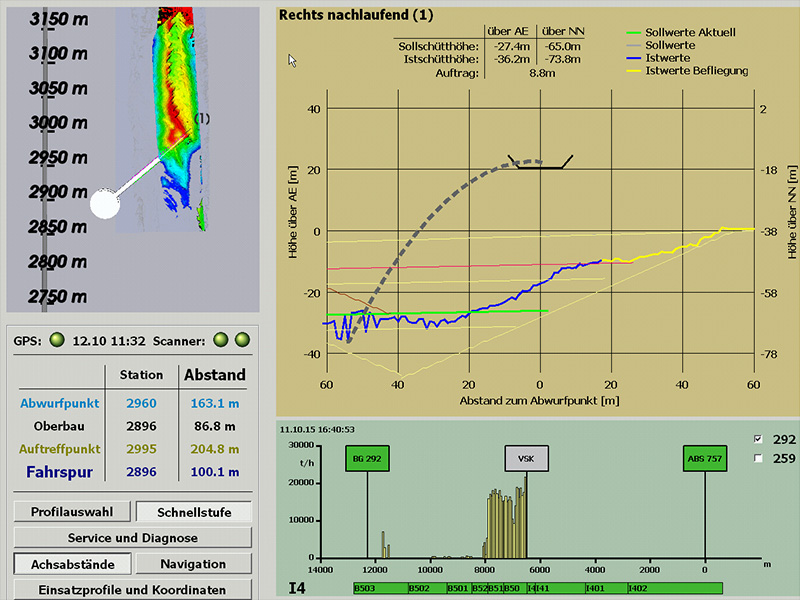

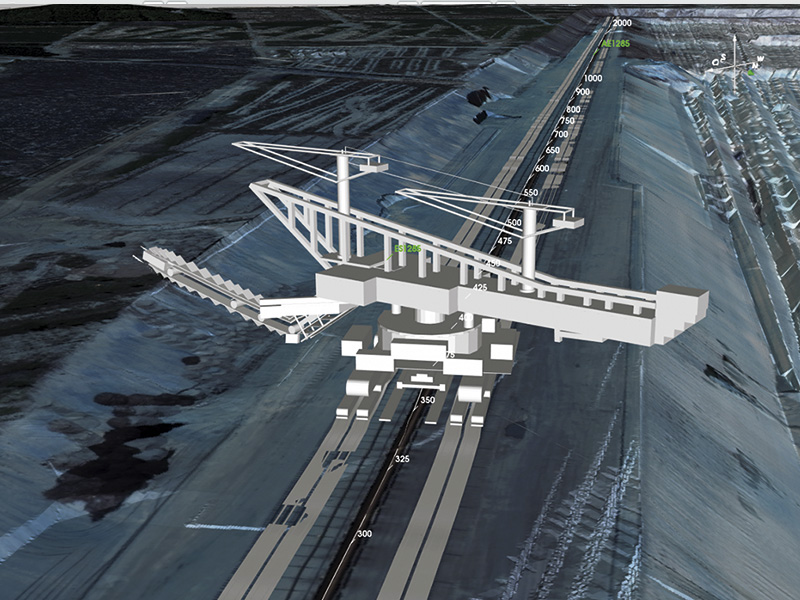

On-site testing

- Supporting excavator and spreader operators

- Compliance with geometric specifications in the excavation and spreader process using the 3D online modelling of large-scale equipment

- Determining the position of the bucket wheel with high spatial (+/- 5cm) and temporal (~5Hz) resolution

- “Distance situation” to the planning areas (work space, embankments, ramps, wells, gauges)

Scheduling systems

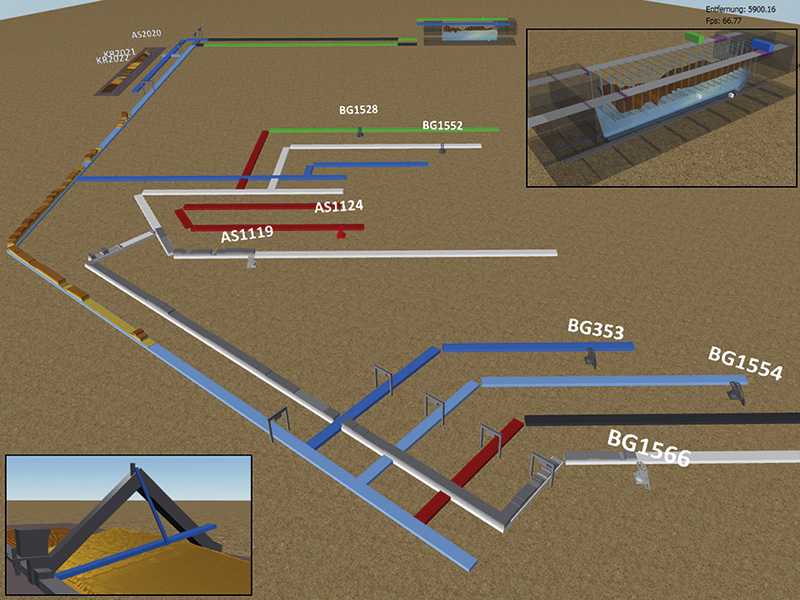

3D modelling in opencast mining:

- Modelling the excavation process and the spreader tipping process

- Modelling the belt situation: Linking, height profiles

- Target / actual comparison of excavation situation: Model surface, planned disk body

Technical specifications

Provisioning of the most diverse technological specifications with a holistic consideration of the entire supply process:

- Revision of default files with relevant data for all consumers and target systems

- Standardised transport mechanism / interface to target systems

- Recovery and use of available default data (history)

Territorial operational control

Execution of various mining projects at a mining site; Modules:

- Terrestrial visual inspection

- Mass calculation

- Inventory calculation

- Machine line creation

Contact persons mining

Andreas Schmidt

T. +49 30 42188-653

F. +49 30 2315467

Mirko Wiedelmann

T. +49 30 42188-749

F. +49 30 2315467

AUCOTEAM GmbH

Storkower Str. 115a, 10407 Berlin

See more automation solutions

Our engineers execute sophisticated projects within the automation for mining operators, as well as for many other sectors:

Energy industry Testing automation Water & waste water Building automation