Automation & Software

Automation & Software Energy Industry

Energy Industry Building Automation

Building Automation

Water & Waste Water Management

Water & Waste Water Management Software for Administrations

Software for Administrations R&D Services

R&D Services Testing & Assembly Automation

Testing & Assembly Automation

You are here: Home » Automation & Software

Automation & Software

Our engineers are tasked with executing sophisticated projects for building automation, for companies operating in the energy technology, as well as water and waste water management, and for mining operations. One additional key point concerns automation solutions for assembly technology involving embedded testing processes.

Für Verwaltungsdienstleistern der öffentlichen Hand entstehen Softwarelösungen für die Rationalisierung der Prozesse.

Innovative solutions for a wide range of industries made by AUCOTEAM

Process automation

We develop customer-specific automation solutions for:

energy industry Building automation Mining operators Water % waste water management

Testing automation/

Test rig construction

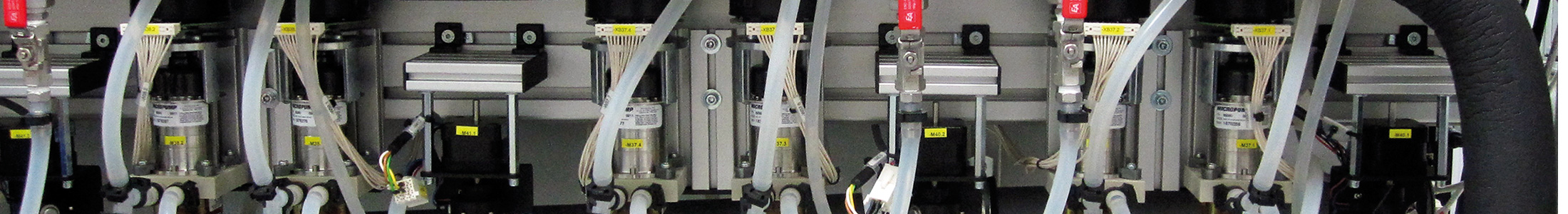

In our testing, metrology and assembly automation business division, we develop and construct customer-specific testing equipment for commercial and scientific tasks.

Authority software

We develop high-performance software solutions together with the top professionals from practice, that offer those working in public sector institutions the platforms needed to render a fast and efficient service:

- Wohngeld WGplus

- Wohnungswesen WWplus

- Elterngeld EGplus

Order development and R&D services

We deliberately focus on innovative niche solutions within the R&D environment. The professional competency of our specialists, the many years of accumulated experience and the flexible approach to handling customer requests act as a guarantee that our clients will only endure a minimum amount of cooperation, coordination and monitoring effort.